Routing & Shaping

Filters

Category

Clear

Show moreShow less

- All Products

- Routing & Shaping

- CNC Routers(7)

- Edgebanders(21)

- Jointers(19)

- Lathes(6)

- Shapers(17)

- Planers(15)

- Moulders(2)

-

Filters : Clear all

Sort by:

Sort by:

Most Popular

Most Popular

Most Recent

Price: High to Low

Price: Low to High

A to Z

Z to A

Brand Ambition 1100 Edgebander Stations Include: Pre-Mill Gluing End Trim Top & Bottom Scrape & Buff In good running condition and still in use under power

$17,000.00

The Class TF 130PS is the workhorse of the SCM shaper line. It has a very robust structure and all the controls can be accessed on the front of the machine for easy use. An integrated sliding table further increases the flexibility of this machine. A mechanical digital reader ensures the precision of the spindle adjustment. 3ph/ 220V 11HP fixed 1 1/4 MK5 interchangeable spindle 5-speed Aluminum fence w/ mechanical adjustment Sliding table Tenoning kit

$15,585.00

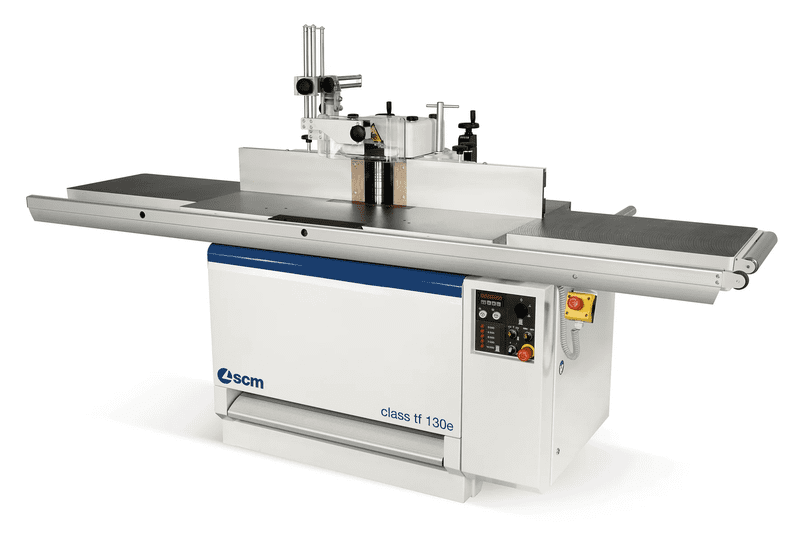

A must for the serious woodworker, the Class TF 130 is the SCM shaper that combines quality and value for your investment. It has a very robust structure and all the controls can be accessed on the front of the machine for easy use. A mechanical digital readout ensures the precision of the spindle adjustment. 3ph /220V 11 HP Fixed 1 1/4 " MK 5 interchangeable spindle 5-speed aluminum fence w/ mechanical adjustments

$12,985.00

The Class TI 120 is one of SCM Groups finest manual tilting spindle shapers. The tilting spindle allows craftsmen to use more creativity in designing high-end, custom products. The quality and flexibility of this machine are especially appealing to architectural millwork operations.

$17,424.00

Holz Heavy Duty 24″ Planer Max Width 630mm Max Thickness 300mm Feed Speed 8, 10, 12 m/min Spindle Speed 4800 rpm Blades 4 straight knife Motor 10hp, 220v 3 phase Weight 1380 lbs

$11,995.00

Holz Paoloni Fixed Spindle Shaper Main spindle speed r/min 1300/2500/3500/5000/6000/8500 Spindle diameter 1 1/4″ Max height 5.9″ Table size 1200×700 mm Main Motor 5.5hp Overall dimensions 1200×800×1240 mm Net weight 838 lbs

$8,900.00

Technical data Max. useful spindle length 140 / 5.5 mm / inches Spindle speed 3000/4500/6000/7000/10000 rpm Max. diameter of the profiling tool 250 / 9.8 mm / inches Max. tool diameter retractable under the table at 90° 320 / 12.6 mm / inches Max. diameter of the tenoning tool 300 / 11.8 mm / inches Three-phase motor power 10 Hp

$43,895.00

Technical data Max. useful spindle length 140 / 5.5 mm / inches Spindle speed 900 – 12000 rpm Max. diameter of the profiling tool 250 / 10 mm / inches Max. tool diameter retractable under the table at 90° 300 / 11.8 mm / inches Max. diameter of the tenoning tool 300 / 11.8 mm / inches Three-phase motor power 13 Hp

$59,785.00

Further enhanced compared to its predecessor with the new end cutting-rounding unit. This new unit allows further processing, saving a substantial amount of time with an ease of processing. This technological solution is unique in its category, where such operations are normally a feature of more expensive and higher level machinery. Technical Data 1ph 10" EYE-S touch screen control Units: Dual pre-mil combined End trim and Corner rounding Top/bottom trim • Work table dimensions mm 3000 x 525 • Min. ÷ max. thickness of rolled edges mm 0,4 ÷ 3 • Max. thickness of edges in strips mm 5 • Min. ÷ max. panel height mm 8 ÷ 50 • Min. panel length/width mm 190/110 • Min. panel length/width with end cutting/rounding unit mm 120/110

$30,395.00

Technical data Min. ÷ max. edge thickness 0,4 ÷ 3 mm Min. ÷ max. edge height 10 ÷ 84 mm Min. ÷ max. panel height 8 ÷ 80 mm Min. panels length/width 290/50 mm Min. internal radius (concave), 0,4 mm thickness 25 mm Min. external radius (convex), 0,4 mm thickness 5 mm Feed speeds 3 - 4 - 5 - 6 - 7 - 8 m/min

$10,865.00

Minimax ME 25 Single Sided Edgebander - Control panel on machine infeed side - Machine frame made of high rigidity ribbed steel to guarantee an excellent support for the operating units - Top thick steel pressure beam with rubber coated wheels - Exclusive feed belt system - Manual adjustment of top beam with automatic positioning of the operating units to the selected panel thickness - Numeric indicator of the selected panel thickness - Wood strip loading device - Glue smoke-specific exhaust outlet; centralized extraction of the other dusts - Panel support roller which can be extended on the entire length of the machine - Safety enclosure - Electrical cabinet with PLC, padlockable main switch and overload protection - Emergency push buttons - Scraping unit (cutter radius 3mm) - Buffing unit (two independent motors – 2,800 rpm) - Adjustable infeed fence with numeric readout - Automatic lowering of the glue pot temperature after temporary non-usage

$19,165.00

With gluing of the panel edge, also with edging solid wood strips up to 5 mm thickness, offers the “very best” performance in edge banders at this level. The features, coupled to its ease-of-use, makes it the perfect edge bander for small woodworking, furniture and panel processing companies. Technical Data • Work table dimensions mm 3000 x 525 • Min. ÷ max. thickness of rolled edges mm 0,4 ÷ 3 • Max. thickness of edges in strips mm 5 • Min. ÷ max. panel height mm 8 ÷ 50 • Min. panel length/width mm 190/110 • Min. panel length/width with end cutting/rounding unit mm 120/110 • Feed speed

$26,895.00

High productivity edge bander with top level performance.

It enables to obtain high quality finished products, without further processing, allowing a considerable saving of time and increasing ease of processing. It is confirmed as the most accessorizable machine in its technological range, with an excellent quality/price ratio.

This edgebander increases productivity with the feed track of the panel brought to a speed of 9 m/min and it guarantees high quality standards in processing thanks to the possibility of working with polyurethane glue, perform grooves, all being extremely easy to use.

It enables to obtain high quality finished products, without further processing, allowing a considerable saving of time and increasing ease of processing. It is confirmed as the most accessorizable machine in its technological range, with an excellent quality/price ratio.

This edgebander increases productivity with the feed track of the panel brought to a speed of 9 m/min and it guarantees high quality standards in processing thanks to the possibility of working with polyurethane glue, perform grooves, all being extremely easy to use.

$37,165.00

High productivity edge bander with high quality performance. me 40, further enhanced compared to the previous version, with the new rounding unit that allows to obtain high quality finished products, without further processing, allowing a considerable saving of time and increasing ease of processing. Technical Data • Work table dimensions mm 3465 x 710 • Min. ÷ max. thickness of rolled edges mm 0,4 ÷ 3 • Max. thickness of edges in strips mm 5 • Min. ÷ max. panel height mm 8 ÷ 50 • Min. panel length/width mm 190/110 Feed speed m/min 9

$37,985.00

Technical data profiset 40 Min./max. working width (finished section) 23/180 mm Min./max. working height (finished section) 6/105 mm Feed speed 6 – 12 m/min Spindles speed 6000 rpm

$38,985.00

Technical data profiset 60 Min./max. working width (finished section) 25 (15 opt.)/230 mm Min./max. working height (finished section) 6/120 mm Feed speed – m/min Feed speed (variable with inverter) 25-May m/min Spindles speed 6000 rpm Axial adjustment of spindles with respect to the worktable 40 mm

$76,795.00

Technical data Max. edgebanding thickness 4 mm Min. - max. panel height 14 - 80 mm Min. panel length/width 200/160 mm Minimum internal radius 25 mm Variable cutters speed 9000 - 15000 rpm

$8,985.00

Technical data T 124 Distance between centers, with copying device mm / inches 1150 / 42.25, 1120 / 44 Centers height (Swing) mm / inches 200 (400) / 7.8 (15.75) 4 chuck speeds rpm 570/1000/1850/2500 Single-phase motor Hp 2.5

$6,535.00

Fixed Spindle Shaper The Minimax TW 45C is a 4 horsepower spindle moulder, with sliding table and a fixed spindle. It is versatile and easy to use, ideal for woodworkers and craftsmen. Featuring a standard 1.25” spindle with dual exhaust ports, T-slot on front of the table, and miter gauge for angled cuts, flip-stops and eccentric clamp. STANDARD EQUIPMENT -Forward/ reverse-run switch -T-Slot on front of table -Micro-adjustable infeed and outfeed fences -1.25” spindle standard -Quick spindle lock for tool changes -Dual exhaust outlets -Tool set and manual included -Miter gauge -Two flip-stops -Eccentric clamp

$5,985.00

Techical Data Working areas X-Y axes dimensions mm 3115 x 1320 Y-axis panel clearance mm 1600 Axes Vectorial speed “Pro-Space” m/min 56 Z-axis panel clearance mm 180 Drilling unit Independent vertical spindles (up to) no. 21 Independent horizonal spindles (up to) no. 10 Rotation speed (max.) rpm 8000 Integrated blade in X, diameter mm 125 Routing unit Motor power (max.) kW (hp) 14 (19) Rotation speed (max.) rpm 24000 Available tools on tool changers (up to) places 25

$125,900.00

Technical Data 4’x’8 Flat Table CNC SAFETY Safety Pro-SPACE AXES MOVEMENT X Axis Positioning Speed 25 Meters/Min (984 Inches/Min) Y Axis Positioning Speed 25 Meters/Min (984 Inches/Min) Automatic Lubrication Yes Drive System X/Y = Helical Rack & Pinion, Z = Ball Screw Dual X-Axis Servos No WORKTABLE X & Y 2468 x 1255 mm (8′ x 4′) Panel Passage 150mm (5.9″) **(100 mm Drilling) Z Axis Stroke 250 mm (9.84″) Number of Vacuum Zones 2 Zones Available Work Areas A-D, E-H Type of Work Table Alumnim Grid Table Reference Pins Std Pins (A,D,E,H) Vacuum Pumps One (1) Becker 300cm/h Pump Vacuum Cups / Clamps None ROUTER HEAD Router Axes 3 Router Spindle HP 13 HP Router Router Spindle Speeds 1,500-24,000 rpm Router Cooling System Air Cooled Aggregate-Ready No Air Blowers for Spindle Yes Measuring Device for Panel Thickness No Measuring Device for Tool Length Yes Dust Hood Manual Setting (4 Positions) Automatic Tool Changer TR11 + Long Tools Mgmt DRILL UNIT/PIGGYBACK Type of Drill Unit F12 Vertical Drills 12 Horizontal Drills 0 Drill Unit Saw Blade No Drill Unit RPM 2,000-8,000 Drill Unit Dedicated Inverter Inverter Shared with Router Dedicated Z2 Axis No Piggyback Unit None AUTOMATION Oflload Rake (Std, NC) Yes Loading Cups No Loading Table No Offload Conveyor No Side Fences No Flow Direction N/A MISCELLANEOUS Transformer 208V, 230V, 460V CFM Required *Estimated 3535CFM Max Power Required *Estimated Compressed Air Requirement *Estimated Additional Options: Cabinet AC Addtl Maestro USB Key Ventilation on Base SOFTWARE/CONTROL PC Console Eye-M PRO OS Windows 10 – 64 bit Pendant Tecpad Active Active Maestro (Basic (3+2), Nest, 3D) Basic (3+2)+ Rect Nesting Connect Connect: 1yr Subscription

$133,900.00

Tech Specs: 5’x 12′ Flat Table CNC Axes Vectorial speed X-Y axes 35 m/min Z axis stroke 250 mm Z axis panel passage 150 mm Routing unit Motor power (max.) 15 (21) kW (hp) Rotation speed (max.) 24000 rpm Available tools on tool changer (max.) 15 places Drilling unit Independent vertical spindles (max.) 12 n. Independent horizontal spindles (max.) 6 n. Rotation speed (max.) 8000 rpm

$149,900.00

Main Features 4’x8′ CNC Router Reinforced base and innovative one-piece frame High Precision, High Load Prismatic Bearing Guides A.C. Servo Motors X, Y & Z Axes Solid State Inverter Controls Router RPM High Performance Aluminium Multifunction Worktable Hiteco Electrospindle 9.5kW (13HP) Pre-arrangement for “Hiteco” Aggregates F7 Drill Head Drilling Unit Managed by Inverter TR 8 Position Tool Changer Tool Touch Probe Manual Lubrication Pump One (1) 300 Cubic Meter/Hour Vacuum Pump Wired Remote Control Console with Integrated PC “Eye-M “

$91,900.00

Technical data Nova tf 110 Max. useful spindle length 140 / 5.5 mm / inches Spindle speed (at 50 Hz) 3000/4500/6000/7000/10000 rpm Max. diameter of the profiling tool 250 / 9.8 mm / inches Max. tool diameter retractable under the table at 90° 320 / 12.6 mm / inches Max. diameter of the tenoning tool with spindle diam. 30-35 (40-50) 300 / 11.8 mm / inches Three-phase motor 8 Hp

$9,985.00

15″ Helical Head Planer The helical cutterhead provides smoother, quieter cutting and finer finish than conventional systems Powerful 3HP TEFC motor controlled with a magnetic switch for safety Three V-belts transfer maximum power to the cutterhead Serrated steel infeed roller and smooth steel outfeed roller allow for 1/8″ maximum depth of cut and trouble free operation Large cast iron handwheel positions table quickly and easily Large, precision ground cast iron table and extensions provide maximum workpiece support Two speed gearbox features automatic chain tensioner One-piece welded steel stand has built-in lockable casters Steel top-mounted return rollers speed repetitive cuts Angled dust chute with 4″ port positions collection hose away from the work area while providing efficient chip and dust collection Table locks firmly in place, preventing movement during cutting

$3,799.99

The Powermatic 8″ Parallelogram Jointer has an extra long 82″ bed length for better work support and is equipped with an innovative single handwheel design that tilts the fence in and out with positive stops at +/-45 and 90 degrees A non-mar insert in the fence contacts the table to avoid scratching the surface during adjustments. The parallelogram design keeps the table in close proximity to the cutterhead for improved finish and allows for a fast depth of cut adjustment. This design also insures the table remains perfectly parallel, even after years of tough duty. The 1/8″ depth limiter control knob gives you quick adjustment ability and safety. A quick twist of the knob will disable this feature. This jointer features a Powermatic controlled chip 3-knife cutterhead for a safe, smooth cut every time. Powerful 2HP or 3HP motors are totally enclosed in a heavily constructed steel stand providing plenty of power for the most demanding jobs. Features: • A non-mar insert in the fence contacts the table to avoid scratching the surface during adjustments. • The parallelogram design keeps the table in close proximity to the cutterhead for improved finish and allows for a fast depth of cut adjustment, insuring the table remains perfectly parallel, even after years of tough duty. • The 1/8″ depth limiter control knob gives you quick adjustment ability and safety. A quick twist of the knob will disable this feature. • Powermatic controlled chip 3-knife cutterhead gives a safe, smooth cut every time. • Powerful 2HP, 1PH motor is totally enclosed in a heavily constructed steel stand.

$4,499.99

• Dust Collection Minimum CFM Required : 800 • Dust Port Diameter (OD/in.) : 5 (dual ports) • Electrical Controls – Magnetic Starter : 24V Magnetic • Fence Size (L x H/in.) : 46 x 5 • Fence Travel (Major and Minor/in.) : 5-3/8 and 3-5/8 • Height (in): 53 • Length (in): 51 • Maximum Diameter Cutter Above Table (in) : 12 • Maximum Diameter Cutter Below Table (in) : 9 • Motor HP : 7-1/2HP • Motor Phase : 3PH • Motor Voltage : 230/460V • Net Weight (lb): 1,100 • Overall Dimensions : 51 x 44 x 53 • Part Number : 1791284 • Prewired : Prewired 230V • Reversible : Yes • Router Bit Collet Diameter (in) : 1/4 and 1/2 • Slide Table Size (in) : 11-1/4 x 51-1/4 • Spindle Diameter (in) : 3/4, 1, and 1-1/4 • Spindle Size Under Nut (in) : 3/4 Spindle – 3-1/2, 1 Spindle – 6-1/4, 1-1/4 Spindle –6-1/4 • Spindle Speed (RPM) : 3000, 4000, 6000, 8000, and 10,000 • Spindle Travel (in) : 7 • Table Inserts : one tilting, two straight • Table Size (in) : 51-1/2 x 33-1/2 • Table Travel (in) : 49-1/4 • Tilting Spindle (deg.) : 5° back, 45° forward • Width (in): 44 • Shipping weight 1,280 lb.

$12,499.99

• Solid steel helical insert head with four-sided carbide insert tooling, eliminates need for adjustment after changing knives, reduces sound levels • Digital readout and simple PC controller make quick and easy table height set ups • Segmented serrated infeed roll with segmented chip breakers has 1/4″ independent yield, for planing multiple height stock • Massive gear box maintains positive feed by using a large chain drive with automatic chain tensioners, to power infeed and outfeed rollers • 3″ diameter infeed and outfeed rollers are supported by four large, sealed, needle bearings for long life • Quick-Set micro-adjustable lever easily raises and lowers table rollers from 0″ to 0.050″ at a touch • Frame machined from heavy cast iron and extra wide side panels with gibs, offers rigid bed support and accurate alignment • Solid pressure bar has wide foot for long wear and can be adjusted on both ends for precise feeding • 3 speed feed selector allows you to quickly change feed rates • Large 32-3/16 x 26 precision-ground table contains two adjustable table rollers for smooth feeding of uneven stock • Dust hood features built-in 5″ dust chute for efficient dust collection • Helical head with four sided inserts • Dust hood with 5″ diameter dust port • Segmented infeed rollers • Segmented chip breakers • Tool kit with pneumatic screwdriver for removing the cutterhead insert blades • Bed Rollers Adjustable from Front : 0″ to 0.05″ • Column Diameter (in) : 2-1/2 • Cuts Per Minute : 30000 • Cutterhead Diameter (in) : 3-3/8 • Cutterhead Speed (RPM) : 5000 • Dust Collection Minimum CFM Required : 600 • Dust Port Diameter (OD/in) : 5 • Feed Rate (FPM) : 30-25-20 • Height (in): 59 • Length (in): 52 • Maximum Depth of Cut (in) : 1/4 • Maximum Full Width Depth of Cut (in) : 1/8 • Maximum Height of Rollers Parallel to Tabletop (in) : 0.05″ • Maximum Planing Thickness (in) : 9 • Maximum Planing Width (in) : 25 • Minimum Planing Length (in) : 10 • Model Number : WP2510 • Motor HP : 15HP • Motor Phase : 3Ph • Motor Voltage : 230/460V • Net Weight (lb): 1,725 • Number of Knives : 168 Four-sided inserts • Outfeed Roller Diameter (in) : 3 • Overall Dimensions : 52 x 36 x 59 • Part Number : 1791303 • Prewired : Prewired 230V • Readout Scale : in/mm • Rollers (in) : (1) infeed, (2) outfeed • Rotation (Forward/Reverse) : Fwd only • Segmented Infeed Roller Diameter (in) : 3 • Table Height Adjust Manual : 1 handwheel revolution = 1/32″ • Table Size (in) : 32-3/16 x 26 • Table Support : 2 column • Tool Supplied : tool kit • Width (in): 36

$18,499.99

Servo Driven Edgebander, Automatic single sided edgebander designed to be used for edgebanding straight vertical profiles with coiled material (veneer and PVC) and with strips (high-pressure laminate and solid wood) with a maximum thickness of 8mm. Machine Base The machine base is made of a tubular steel structure and is designed to assure maximum stability and accuracy. Electronic Top Pressure Beam All operating units raise and lower simultaneously when the pressure beam is adjusted. No adjustment is required for the glue roller when changing panel thickness. The pressure beam has two rows of staggered pressure rollers with steel bearings. Capacities and Speed • Edgebanding thickness: .4mm – 6mm (.016-1/4”) • Guillotine capacity: 3mm • Feed speed: 36 ft/min. • Panel height: 3/8” min – 2 1/8” max • Minimum panel length: 5 1/2” • Minimum panel width: 2 3/8” • Minimum distance between panels: 22”

$88,000.00

The right spindle moulder for demanding craftsmen and carpentries, thanks to its customization and flexibility. The minimax tw 55es is the culmination of years of experience in manufacturing quality solid wood SCM products. This 4-speed heavy duty machine is standard with both a sliding table and tilt! The slider has hardened steel guide ways and precision bearings, so it incorporates the exact technology found in our top selling sliding table saws! The hood has memory pins so if removed, it will go right back into the same position, making this shaper accurate and repeatable.

$11,974.00 - $12,628.00

$12,628.00

$11,974.00

Technical Specifications Worktable Dimensions: 1200 x 730mm Working Length of Spindle (C.E.) Diam. 30-35 (40-50): 140mm (180) Spindle Base Projection from Table: 52mm Spindle base projection from table with interchangeable spindle: 92mm Max tool diam. retractable under worktable with rings (with "Fast" section table): (300 x 85mm) Spindle fence stroke w/ mechanical programming (positioning with respect to the spindle axis): 125mm (from -125 to +125) External diameter of exhaust outlet on spindle moulder hood: 120mm External diameter of exhaust outlet on base (for the forced electrospindle aircooling 7.5 kW): 120mm Air flow speed of exhaust system: 20 M/sec Exhaust system air consumption: 1700 M3/hr

$17,585.00

$23,895.00

• Motor: 2HP, 1PH, 230V, 9A • Cutterhead Speed (RPM): 7,000 • Cutting Capacity (W x D) (In.): 8 x 1/2 • Table Size (L x W) (In.): 73 x 8-1/2 • Table Height from Floor (In.): 32 • Infeed Table Length (In.): 35-1/4 • Outfeed Table Length (In.): 35-1/2 • Fence Size (L x H) (In.): 38 x 4-3/4 • Fence Tilt (Deg.): 45 Forward, 45 Backward • Fence Positive Stops (Deg.): 45, 90, -45 • Dust Collection Minimum CFM Required (CFM): 450 • Dust Port Outside Diameter (In.): 4 • Recommended Circuit Size (Amps.): 20V

$2,899.99 - $3,499.99

$3,499.99

$2,899.99

• 4″ port for dust collection • 1HP TEFC Motor • Two push blocks • Dust collection port • Cutterhead guard • Industrial push-button switch • Cutterhead Speed (RPM) : 6000 • Cutting Capacity (W x D/in) : 6 x 1/2 • Dust Collection Minimum CFM Required : 800 • Dust Port Diameter (OD/in) : 4 • Fence Positive Stops (deg.) : 45 left, 90, 45 right • Fence Size (L x H/in) : 38 x 4 • Fence Tilts (deg.) : 45 left, 45 right • Height (in) : 37.5 • Infeed Table Length (in) : 32-1/2 • Length (in) : 66 • Model Number : 54 • Motor Amps : 13/6.5 • Motor HP : 1HP • Motor Phase : 1PH • Motor Voltage : 115/230V • Net Weight : 328 pound • Outfeed Table Length (in) : 32-1/2 • Overall Dimensions : 66 x 24 x 37-1/2 • Part Number : 1791317K • Prewired : Prewired 115V • Table Height (in) : 31-1/2 • Table Size (L x W/in) : 66 x 7-1/4 • Width (in) : 24 • Shipping weight 328 lb.

$1,999.99 - $2,399.99

$2,399.99

$1,999.99

The Nova F 410 T is a heavy duty, long bed 16” jointer designed to meet the needs of the most demanding environments. It features cast iron tables, tilting fence, and a quick change Tersa or Spiral Cutterhead.

$11,963.00 - $12,617.00

$12,617.00

$11,963.00

The Nova F 520 T is a heavy duty, long bed 20” jointer designed to meet the needs of the most demanding environments. It features cast iron tables, a tilting fence and a quick change Tersa cutterhead.

$15,887.00

Technical data L’invincibile f 7 Cutterhead working width 520 / 20 mm / inches Cutterblock diameter / n° of standard knives 120/4 mm/n° Dimensions of standard knives 520 x 35 x 3 mm With XYLENT Spiral Helical Cutterhead: 120/84 mm/n° Cutterblock diameter / n° of standard knives 15 x 15 x 2.5 mm Dimensions of standard knives Jointer bed length 3008 / 118 mm / inches Three-phase motor 11 Hp Max. stock removal 8 mm

$20,575.00 - $22,427.00

$20,575.00

$22,427.00

About This Machine: The K360 is an automatic single sided edgebander designed to be used for edgebanding straight vertical profiles with coiled material (veneer and PVC) and with strips (high-pressure laminate and solid wood) with a maximum thickness of 6mm. Machine Base The machine base is made of a tubular steel structure and is designed to assure maximum stability and accuracy. Top Pressure Beam All operating units raise and lower simultaneously when the pressure beam is adjusted. No adjustment is required for the glue roller when changing panel thickness. The pressure beam has two rows of staggered pressure rollers with steel bearings. Capacities And Speed – Edgebanding thickness: .4mm – 6mm (.016-1/4”) – Guillotine capacity: 3mm – Feed speed: 36 ft/min. – Panel height: 3/8” min – 2 1/2” max – Minimum panel length: 5 1/2” – Minimum panel width: 2 3/8” – Minimum distance between panels: 20” Glue Station Teflon coated glue pot to facilitate glue changeover. Warm up time is approximately eight to ten minutes. The unit is also equipped with a quick disconnect plug for changing from one pot to another.

$46,000.00 - $75,000.00

$75,000.00

$57,000.00

$46,000.00

High performance and versatility: olimpic k 560 is designed for companies requiring to process many panels per day even though they may be different from one to another. olimpic k 560 has several solutions that guarantee always the best machining on any panel type. Capacities and Speed – Edgebanding thickness: .4mm – 6mm (.016-1/4”) – Guillotine capacity: 3mm – Feed speed: 40/60 ft/min. – Panel height: 3/8” min – 2 1/8” max – Minimum panel length: 5 1/2” – Minimum panel width: 2 3/8” – Minimum distance between panels: 20”

$79,000.00 - $90,000.00

$90,000.00

$79,000.00

The machine base is made of a tubular steel structure and is designed to assure maximum stability and accuracy. Pressure Beam: All operating units raise and lower simultaneously when the pressure beam is adjusted. No adjustment is required for the glue roller when changing panel thickness. The pressure beam has digital height indicators and a double row of pressure rollers with steel bearings Capacities And Speed: – Edgebanding thickness: .4mm – 3mm (.016-1/8”) – Guillotine capacity: 3.0mm – Feed speed: 30 ft/min. – Panel height: 3/8” min – 1 15/16” max – Minimum panel length: 5 1/2” – Minimum panel width: 2 3/8” – Minimum distance between panels: 22” Glue Station Teflon coated glue pot to facilitate glue changeover. Warm up time is approximately eight to ten minutes. The unit is also equipped with a quick disconnect plug for changing from one pot to another.

$36,000.00 - $62,000.00

$36,000.00

$46,000.00

$62,000.00

L’invincibile s 7 Cutterhead working width mm / inches 630 /24 With TERSA Straight-knife Cutterhead: Cutterblock diameter / n° of standard knives Dimensions of standard knives mm/n° mm 120/4 630 x 35 x 3 With XYLENT Spiral Helical Cutterhead: Cutterblock diameter / n° of standard knives Dimensions of standard knives mm/n° mm 120/84 15 x 15 x 2.5 Min. – max. planer working height mm / inches 3.5 – 300 / 1 / 3 – 11.75 Planer feed speed m/min 4 – 20 Three-phase motor Hp 15 Max. stock removal mm 8

$25,775.00 - $28,313.00

$25,775.00

$28,313.00

5hp Motor 20″ Width Specifications: Prewired: 230V Single or Three Phase Dust Collection Minimum CFM Required : 900 Dust Port Diameter (OD/in) : 5 Feed Rate (FPM) : 24 and 31 (16 and 20 with gear change) Height (in) : 41.375 Length (in) : 26 Maximum Depth of Cut (in) : 3/32 Maximum Planing Thickness (in) : 8 Maximum Planing Width (in) : 20 Minimum Planing Length (in) : 6-3/4 Net Weight : 800 lb Number of Speeds : 4 Overall Dimensions : 26 x 36-5/8 x 41-3/8 Readout Scale : in/mm Rotation (Forward/Reverse) : Fwd Table Size (in) : 20 x 55-1/2 Table Support : 4 column Width (in) : 36.625 Shipping weight 890 lb.

$4,449.99 - $5,999.99

$5,999.99

$5,999.99

$4,449.99

$4,449.99

Technical data Cutterhead working width mm 630 With TERSA Straight-knife Cutterhead: Cutterblock diameter / n° of standard knives Dimensions of standard knives mm/n° mm 120/4 630 x 30 x 3 With XYLENT Spiral Helical Cutterhead: Cutterblock diameter / n° of knives Dimension of standard knives mm/n° mm 120/105 15 x 15 x 2.5 Min. – max. planer working height mm 3.5 – 300 Planer feed speed m/min 4 – 20 Three-phase motor Hp 12

$23,953.00 - $25,043.00

$23,953.00

$25,043.00

Type of Cutterhead Straight Knife Knife Size (L x W x T) 22-1/8 x 7/8 x 1/8 Cutterhead Speed (RPM) 4,800 Cutterhead Diameter (In.) 3-1/4 Cuts Per Minute 19,200 Number of Knives 4 Maximum Depth of Cut (In.) 3/16 Maximum Planing Width (In.) 22 Maximum Planing Thickness (In.) 9-1/4 Minimum Planing Length (In.) 10 Feed Rate (FPM) 20/30 Segmented Infeed Roller Diameter (In.) 3 Outfeed Roller Diameter (In.) 3 Bed Rollers Adjustable from Front 2 Table Size (L x W) (In.) 32-1/4 x 24 Table Support 2 Column Dust Collection Minimum CFM Required (CFM) 900 Dust Port Outside Diameter (In.) 5 Motor Power (HP) 7-1/2 Motor Phase 1 Motor Voltage (V.) 230 only Recommended Circuit Size (Amps.) 50

$8,499.99 - $10,899.99

$10,899.99

$10,899.99

$8,499.99

The Nova S 520 T is a heavy duty, 20” planer designed to meet the needs of the most demanding environments. It features a monoblock base, work table with support rollers, and a Tersa cutterhead.

$15,233.00 - $15,887.00

$15,233.00

$15,887.00

Edge thickness mm 0,4 - 6/8 (12 opt.) Panel thickness mm 8 - 60 Feed speed m/min 12 - 18 Compressed air bar 6

$115,000.00

• TABLE BED CUT AREA: 51” X 97” WITH ATC OR 55" X 97" WITHOUT ATC • GANTRY CLEARANCE: 8" STANDARD • MAXIMUM TRAVEL SPEEDS ON X & Y: 1000IPM STANDARD • MAXIMUM TRAVEL SPEEDS ON Z: 500IPM • Z TRAVEL: 9” • MACHINE WEIGHT: 2100-2600 LBS • MACHINE FOOT PRINT (INCLUDING GANTRY): 79” X 116” X 69" (78" WITH ATC) • MACHINE STRUCTURE: STEEL TUBE FRAME- WELDED • GANTRY STRUCTURE: LARGE TUBE STEEL WITH TUBE STEEL GANTRY UPRIGHTS • DRIVE SYSTEM: X RACK AND PINION & DUAL Y AXIS RACK AND PINION WITH SHOPSABRE FLOATING DRIVE TECHNOLOGY - Z AXIS BALL SCREW • BEARING SYSTEM: 25MM LINEAR GUIDE RAILS AND BEARINGS WITH QUAD ROLLER SETS AND TRIPLE SEAL BY THK/HIWIN • CONTROLLER: SHOPSABRE WINCNC ADVANCED CONTROLLER • PC SYSTEM: INCLUDED WITH SSD HARD DRIVE AND PCI CONTROLLER BOARD INSTALLED • NETWORKABLE: YES • PC TO PC CONNECTIVITY FOR DIAGNOSIS AND TRAINING: YES • SOFTWARE: VECTRIC • TECH SUPPORT: INCLUDED – LIFE-TIME • CONTROLLER SOFTWARE UPDATES: INCLUDED • MANUFACTURER: UNITED STATES – SHOPSABRE FACILITY –MINNESOTA • FULLY ASSEMBLED• PRE-TESTED• LIFE-TIME TECH SUPPORT (PHONE/EMAIL/PC2PC)

$42,500.00

specifications: Motor: 1 HP, 3 PH, 230V, 60 HZ Input Power Requirement: 1 PH, 120V Recommended Circuit: 15 Amp Speed Range: 15-3,600 RPM Spindle Thread: 1-1/4" x 8 TPI Spindle/Quill Taper: MT2 Index Positions: 24 positive locking Swing Over Bed: 14-1/4" Swing Over Tool Rest Base: 10-3/4" Distance Between Centers: 19-1/4" Bed Gap: 1-3/4" Tool Rest: 1" D post x 8" W Overall Dimensions (highest position): 52" x 24" x 48-1/2" Overall Dimensions (lowest position): 52" x 24" x 38" Stand Height: 34'' to 46'' (to centerline of chuck) Shipping Dimensions: 25.56" x 27.56" x 13.78" Shipping Weight: 277 lb.

$2,799.99

Specifications: Motor: 1 HP, 3 PH, 230V, 60 HZ Input Power Requirement: 1 PH, 120V Recommended Circuit: 15 Amp Speed Range: 15-3,600 RPM Spindle Thread: 1-1/4" x 8 TPI Spindle/Quill Taper: MT2 Index Positions: 24 positive locking Swing Over Bed: 14-1/4" Swing Over Tool Rest Base: 10-3/4" Distance Between Centers: 19-1/4" Bed Gap: 1-3/4" Tool Rest: 1" D post x 8" W Overall Dimensions: 52" x 24" x 18" Shipping Dimensions: 34.25" x 18.9" x 22.83" Shipping Weight: 206 lbs.

$2,399.99

Loading...